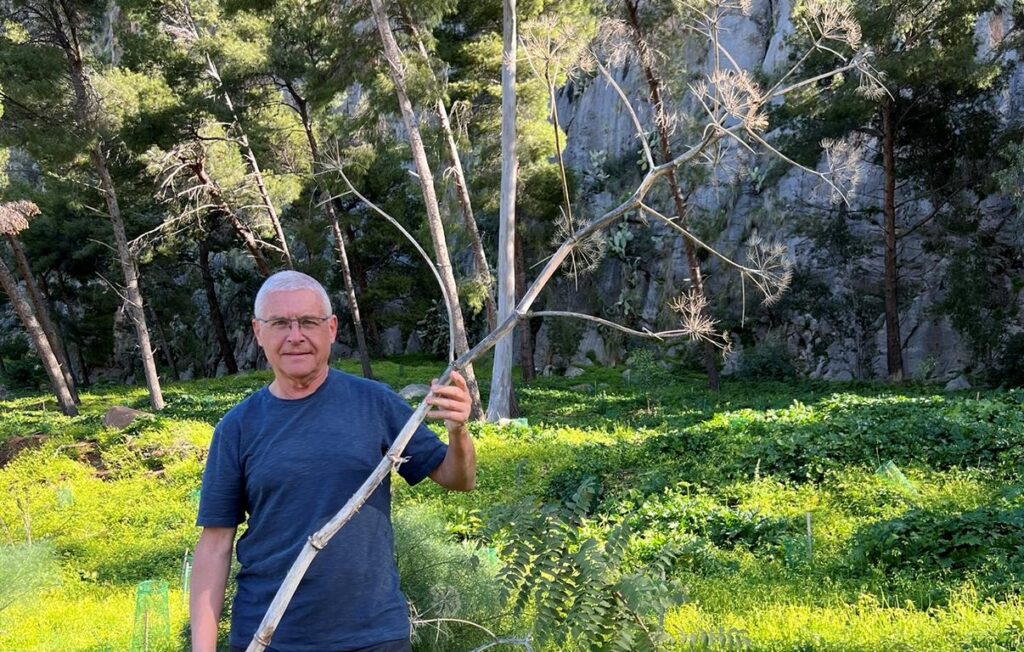

Various internet pages and YouTube channels describe lighting fire with stalks of giant fennel (Ferula communis) as easy. I doubted these claims, so I tested them myself. The outcome was sobering, which I will describe in the following article. I also checked the possibility of using them to transport fire.

Lighting fire with a Fire rod

Fire rods are one of those gadgets modern survivalists think they need for their back-to-nature experience. Except they overlook that when unexpectedly stranded in nature, there is no shop to buy such rods when required. Nevertheless, I tested the effect of fire rod sparks on Giant Fennel pith on three pieces of such fennel stalks.

On the first trial, I kept the fire rod away from the pith for the photo, which did not matter, as the pith caught the spark quickly and started smoldering.

However, this smoldering only lasted as long as I forcefully blew into the ember.

I could not even stop blowing into the embers and using the camera to take a photo because the glowing stopped immediately if there was no additional oxygen supply.

The ember died about 10 seconds after blowing into it and went cold. To make it short, the same happened in the second and third trials on different pieces of Giant Fennel piths again.

The result of fire rod sparks on pieces of dry pith of a Giant Fennel collected in March near Bronte in Sicily is that sparks are easily caught. However, the embers only live if somebody forcefully blows into them. When left in the surrounding air, these embers will die quickly without blowing.

Bow drill fire lighting

I did bow drilling with Giant Fennel stalks twice, once in situ in Sicily and once at home. At the first trial in Sicily, I used parts of the bow drill, which I had on hand where the Giant Fennel grew. Therefore, the string, bow, and holding block were improvised.

The result of this trial was as follows:

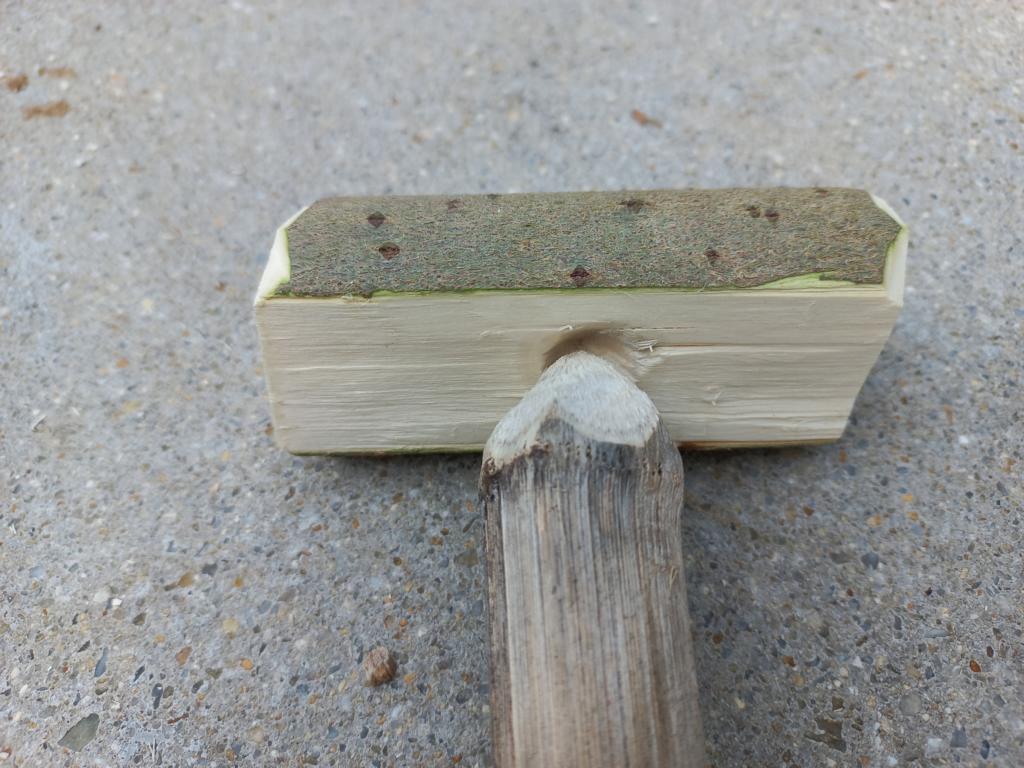

- The hearth board and spindle showed heavy glazing; scratching it off and starting again did not work. Also, adding some grains of sand was unsuccessful. Due to the soft pith material, I had to increase the rotation speed and heavily reduce the downward force on the holding block.

- The shaved material from drilling remained fluffy throughout the trial and did not form an ember below the V-slot.

- The spindle tip in the holding block rubbed off very fast due to the softness of the pith. I had to tighten the string considerably to overcome the spindle tip’s friction force.

As a result of this trial, I could not create an ember suitable for lighting a fire.

I did the second test of bow drilling with stalks of Giant Fennel at home under controlled conditions. The string was paracord, and the bow and holding block were made from green wood. The top end of the spindle was now carved in the node wood of a stalk, which is considerably more robust than the pith between the nodes.

Nevertheless, all these improvements did not help. Finally, an ember suitable for lighting a fire was impossible to create with this Giant Fennel wood.

Reasons for not creating a suitable ember

The shavings remain fluffy, not solidifying to an ember.

Under the microscope, it can be seen that there are just brownish particles and very seldom black-charred pieces of the strings within the pith. The temperature on all these brownish particles was not high enough to form a solid ember before they were removed through the V-slot to the outside.

At all three drilling tests at home, the spindle’s bottom end was shaped similarly. The material’s hardness is lower in the middle of the stalk compared to the area between the outer layer and the middle. In my article about Giant Fennel stalks for building material purposes, see here, I measured the Shore-D hardness of the material. These measuring results fully coincide with this trial result.

Using the stalk’s node area for the spindle top and a green holding block proved successful. There was no longer any problem with premature wear of the spindle top.

Although the rotation speed was kept high and the downward pressure of the spindle low, the distance between the two drilling holes next to each other was too low. As the stalk material was so soft, the drilling pits #2 and #3 broke before at 2/3 of the total stalk thickness.

After these trials, I am convinced that Giant Fennel stalks are unsuitable for lighting fire with a bow drill.

Hand drill for lighting a fire

After doing the trials with a fire rod and bow drills, I did not pursue a hand drilling trial. The reason is two-fold:

- Giant Fennel stalks do not grow straight but change their direction to an angled opposite side at every leaf axle (node). Long enough internode pieces – straight enough for hand drilling – are only available at the lower part of the stalk. However, these parts are thick in diameter. At a straight internode length of 40cm / 16”, the thickness of the stalk will be around 4cm / 1.6’’.

- The spindle of a hand drill has to be thin, like a middle finger. Only a certain overlapping length is available for rotating the drill between two human palms and fingers. The spindle should turn at least two times around its axis within this length. Therefore, a thin spindle is needed. Turning around a 4cm / 1.6” thick stalk will take a length of 12,6cm / 4.96’’. Which is only one turn of the spindle in one rubbing direction. This will not generate enough heat for an ember.

Because of these two reasons, the claim of a particular person on the internet that he created six times embers with a Giant Fennel hand drill is highly doubtable. However, I would highly appreciate any critical and constructive comments if somebody has additional experience with this material.

Lessons learned from lighting fire with Giant Fennel stalks:

- The pith of a Giant Fennel stalk will take sparks of a fire rod well, but the resulting ember will die soon if it is not blown upon continuously.

- Bow drill shavings remain fluffy and are brownish without forming a solid ember.

- The internode area of Giant Fennel stalks is physically more robust and should be used for spindle top and -bottom.

- Bow drilling pits on a hearth should be kept wide apart to not break away under strain.

- Due to their physical sizes, Giant Fennel stalk pieces are unsuitable for hand drilling.

Further readings about Fire-making on this website:

Creating fire with a magnifying glass

Hadza hand drill friction fire

Bow Drilling – following the method of Mattias Norberg

Batwa pygmies traditional fire lighting method

Manketti wood for friction fire lighting

Bushscout UK’s fire bundle basket

Fire lighting with Flint & Steel

Hand drilling in UK as taught by Dave Watson

Bow drill standard procedure by Dave Watson

Bow drilling in Australia by Gordon Dedman

Hand drill friction fire lighting in Australia

Creating fire by hand drill in Namibia

Australian friction fire wood species

.