In the northeastern parts of Namibia, Ju//hoansi Khoi-san bushmen preferably use Manketti wood (Schinziophyton rautanenii) for friction fire lighting, at least in areas where Manketti trees are growing. Such areas have slightly higher elevations compared to savanna bushveld vegetation. Both parts of the fire lighting set, the hearth board, and spindle, are made from the same branches of these trees. Therefore, both have nearly the same diameter. In areas where no Manketti trees are growing, they use White raisin bush (Grewia bicolor) spindles, and for base woods, various Commiphora sp..

Choosing the correct wood for a fire-lighting set

Suitable wood is collected from young Manketti trees and never from mature ones. Mature Manketti trees start fruiting at the age of 25 years. A description of these nuts (Mongongo- or Manketti nuts) and their uses can be found at this link. At this age, they already developed a massive trunk and are challenging to climb. On young Manketti trees, a multitude of dead branches can be found. These branches could be suitable for friction fire lighting. But many of them are already decayed by rotting or wood borers. Close inspection and debarking of these branches must be done before collecting them for further use.

Manketti wood of young branches is exceptionally light, with an air-dry wood density of 0,17 – 0,27 g/cm3 at a moisture content of 12%. These figures were obtained from the African Wood Database, which can be found here.

Dry wood is whitish in color, grained along the axis, and has a medium-sized spongy core. These durable grains along the spindle axis improve friction when rubbing against the hearth board and easily develop an ember.

Hand drill friction fire with Manketti wood

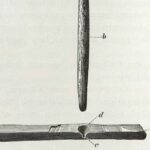

The set-up of the hand-drill set is simple. Firstly, a flat plane on top of the hearth board is carved, and an indentation is made as an anchor point for the spindle. Secondly, a notch is cut perpendicular to the flat plane to receive the ember. And thirdly, a bundle of flat grass blades is laid onto the ground. Above that grass bundle, a knife blade is positioned below the notch for receiving the ember. We used a knife blade on this occasion, as Ju//hoansi Khoi-san people always use heat-resistant materials to obtain the ember and never use leaves or bark as it is common in other parts of the world.

Hand drilling is commonly done by two people, with alternate drilling after every spindle length. They are encouraged by surrounding Ju//hoansi Khoi-san calling in unison ‘Khwa Khwa khwei’ (meaning: Fire – come).

Lessons learned about Manketti wood for friction fire lighting:

- Care has to be taken only to collect solid Manketti wood branches.

- Suitable branches have to be debarked.

- Hand drilling done by two people is more manageable than done alone.

Further readings about Fire-making on this website:

Creating fire with a magnifying glass

Hadza hand drill friction fire

Bow Drilling – following the method of Mattias Norberg

Giant Fennel stalks for lighting fire

Batwa pygmies traditional fire lighting method

Bushscout UK’s fire bundle basket

Fire lighting with Flint & Steel

Hand drilling in UK as taught by Dave Watson

Bow drill standard procedure by Dave Watson

Bow drilling in Australia by Gordon Dedman

Hand drill friction fire lighting in Australia

Creating fire by hand drill in Namibia

Australian friction fire wood species

.