Friction fire hand drills are usually not the first choice for fire lighting in the Northern Hemisphere, as they are regarded as a strenuous technique, especially in cold and humid environments. Dave Watson proved this perception is incorrect under overcast Northern Wales weather conditions. He produced an ember as fast with hand drilling in the UK as with a bow drill.

Materials used for friction fire hand drills in boreal forest biomes in the Northern Hemisphere

Hearth board for hand drill friction fire method

Dave uses dry Wild clematis (Clematis vitalba) wood as a hearth board, which he cuts into 1.5-2 cm thick slices. This thickness is ideal for drilling long enough to minimize the distance (and therefore heat loss) for falling charred powder to create an ember in the notch.

Spindle for hand drill friction fire method

For spindles, he either uses hazelwood (Corylus sp.) with a tip of elder wood (Sambucus nigra) or a uniform spindle of elder wood. According to Dave, elder shoots should preferably be collected from a bush or tree, which is not fully exposed to sunlight, as in this case, the shoots tend to grow too fast and only develop a fragile wooden area with a large pit inside. It is far more likely to get good wood from shaded bushes. He collects all his elder shoots in wintertime, containing the least water from forest bushes. Nevertheless, every single elder shot has a pit of a different size.

For hand-drilling spindles in the UK, Dave cuts about 10 cm long parts of elder shoots and removes the spongy pit to a depth of about 3 cm. After that, he carves onto his Hazel, shoots a matching prop with a 90-degree shoulder, and matches both pieces mechanically together. They will never come apart again, and he got a perfectly straight stick with a tip of softer wood and a small surface area (as only the elder wood will grind, not the elder pit). On average, the spindles are, in total, about 80 cm long.

.

.

.

.

Kindling for hand drill friction fire method

Dave receives the ember in a dry grass nest, filling in an additional kindling primer. He usually uses thistle or fireweed (Rosebay willowherb; Chamaenerion angustifolium) fluff.

Specifics of hand drill fire-making

Before Dave starts, he wets his hands with water to better grip the whirling. Whenever he stops, he wets his hands again before starting. When doing it myself, I found a big difference in whether or not to apply water to the hands, so it is recommended.

Dave does not hold down the hearth board when hand drilling in the UK with his feet. Before he starts, he ensures the board is not moving, so holding it down during drilling is unnecessary.

Dave drills using nearly the whole spindle length, which is considerably longer than it is rotated before setting a new grip in Australia or Africa. He then uses his upper body to apply downward force to his hands by kneeing backward from the spindle.

Afterward, we practiced a similar technique in a relay fashion. Three persons always kneeled around a hand drill and wetted their hands. The first one held down the hearth board with two fingers; the second one rotated the spindle and, when reaching the lower point, shouted, ‘Take over.’ At this command, the third one took over at the top, and this went around until we created an ember, which—again—happened surprisingly fast.

Only about three whole spindle strokes were necessary for pre-burning. A small notch was cut, and a wood chip was laid underneath. For the actual burning action, not more than about five full spindle strokes were necessary to produce an ember.

Lessons learned by Dave Watson about friction fire hand drilling

- Friction fire hand drilling is – with the availability of suitable materials – also done quickly in cold and humid climates.

- Harvest elder shoots from shaded bushes in wintertime

- Prepare a Clematis hearth board and dry it out properly

- Train to match Elder tips with Hazel shoots for hand drill spindles

Global Bushcraft Symposium 2022 (GBS2022) and Dave Watson

GBS2022 was held from 27th-31st July 2022 at Llyn Tegid (Bala Lake), within Snowdonia National Park, in North Wales, UK.

Dave set up his company ‘Woodland Survival Crafts’ in 1995 following ten years of building the activities programs and the teams of instructors. In 2007, he instigated the development of the Bushcraft Professional Practice group within the Institute for Outdoor Learning, which promotes the good practice of wilderness-based skills within education. He was awarded Leading Practitioner within the IOL. With the Global Bushcraft Symposium 2022, Dave spoke and led the firecraft theme camp.

Dave reviewed this article on August 11, 2022, suggested one comment that was added, and had no further objections.

Further readings about Fire-making on this website:

Creating fire with a magnifying glass

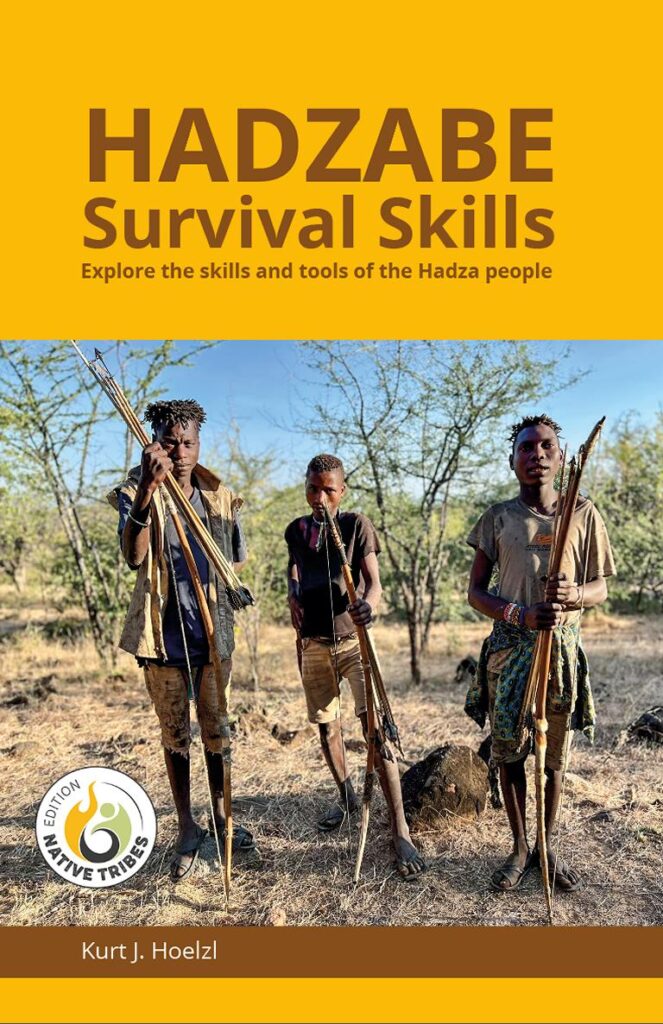

Hadza hand drill friction fire

Bow Drilling – following the method of Mattias Norberg

Giant Fennel stalks for lighting fire

Batwa pygmies traditional fire lighting method

Manketti wood for friction fire lighting

Bushscout UK’s fire bundle basket

Fire lighting with Flint & Steel

Bow drill standard procedure by Dave Watson

Bow drilling in Australia by Gordon Dedman

Hand drill friction fire lighting in Australia

Creating fire by hand drill in Namibia

Australian friction fire wood species

.