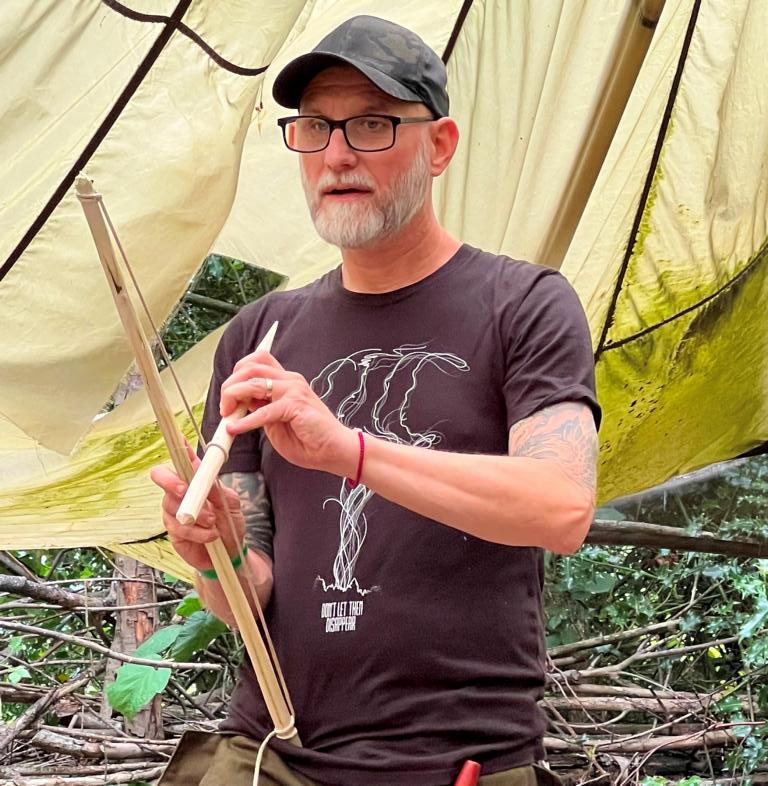

At the Global Bushcraft Symposium 2022 in Wales/UK, the Swede Mattias Norberg demonstrated his method of creating fire by bow drilling. Sweden has a rich outdoor tradition, and it was a privilege to meet him there, as he has deep knowledge and experience on this subject. Mattias is the author of the book ‘Konsten att Elda’ (‘The Art of Fire’), which delves into this subject matter in great detail but is currently only available in Swedish. He has long been an instructor with the Swedish Survival Guild, an association of all individuals and organizations in Sweden dealing with bushcraft and survival topics.

Different types of wood and tinder are available in every biome worldwide, but the principles of fire-making with the bow remain the same. For us, Bushcraft- and Survival people, fire friction with the bow is nothing new. Therefore, I will not delve into the basic process of bow drilling but only address those details that we can learn from Mattias to improve our skills.

Types of wood in Boreal coniferous forests (Taiga) for bow drilling

Mattias demonstrated various types of wood that he has successfully used for the base wood and spindle of bow drills. He always combines the same types of wood for both sticks. The following wood samples were shown:

- Alder, European- (Alnus glutinosa)

- Ash, Common- (Fraxinus excelsior)

- Beech, European- (Fagus sylvatica)

- Elder (Sambucus nigra)

- Elm, Wych- (Ulmus glabra)

- Hazel, Common- (Corylus avellana)

- Juniper, Common- (Juniperus communis)

- Linden, Small-leaved- (Tilia cordata)

- Maple, Norway- (Acer platanoides)

- Maple, Sycamore- (Acer pseudoplatanus)

- Oak, Pedunculate- (Quercus robur)

- Pine, Scots- (Pinus sylvestris)

- Poplar, Trembling- (Populus tremula)

- Spruce, Common- (Picea abies)

- Spruce, Common-, Root (Picea abies)

- Willow, White- (Salix alba)

This is a wide variety of wood types. Mattias’ approach is not to collect wood in the forests, take it home, dry it, and test it there. Instead, he goes into the forest, collects the wood he needs or wants to test, and friction fires directly on the spot with the collected wood.

General rules for selecting wood for bow drilling

He applies the same method for selecting wood types, which is generally customary. He looks for a dry, ‘white’ piece of wood and tests the penetration depth with his thumbnail. The wood is suitable for bow drilling if a groove about 1 mm deep can be formed. If it is too soft, the rotation speed must be increased, the pressure reduced (as with elder for hand-bow drilling), and vice versa for hardwoods (e.g., beech wood).

Mattias also does not hesitate to use coniferous wood from spruces and pines. Indeed, due to their wide availability, he ranks spruces as the most important bow drill wood in boreal coniferous forests. He selects small, dead, and dry spruces still standing upright and uses a thin part of the upper trunk for the spindle and the base wood, one from the thicker, lower area.

He also uses horizontally growing branches of dead spruces and pines for these two functional parts. However, care must be taken to prevent moisture from rain or snow on the horizontally standing branches from causing rot. Wood parts with beetle tunnels under the bark are avoided for spindles, whether standing upright or as branches. These tunnels cause a mechanical weakening of those encircled areas by the cord and significantly disrupt the round movement and cord tension.

Not surprisingly, he does not use woods with resin blisters inside or fat wood from pines for a bow drill set.

Shapes and sizes of bow drill components

Base wood

Base woods should have three flat sides: top, bottom, and perpendicular on one side, about 1.5-2 cm thick. The top surface serves as the spindle attachment, and the side perpendicular to it serves as a slot of consistently equal width. However, Mattias also flattens the bottom side of the base wood to prevent possible pendulum movement during drilling. He explains the thinness of the base wood by the fact that it is sufficient for a successful drilling process, and the low height prevents the friction powder from cooling too much.

In contrast to many other experts and most indigenous peoples, he places the spindle’s attachment point relatively far into the center of the drilling base wood. After pre-burning, he cuts a deep notch, the width of which encompasses about 1/8 of the outer circumference of the pre-burned hole.

Spindle

Mattias recommends a fully extended hand span spindle length plus one finger length. He does not place much emphasis on spindle diameter but stresses the need for a long and very pointed spindle end. The lower end of the spindle, i.e., the friction side, is carved into a semicircle, and he debarks the entire spindle.

Bow and cord

Mattias uses a green, straight, and sturdy stick as a bow, which he also completely debarks. The stick’s length should reach from the armpit area to the end of the last finger of the extended hand. A string-holding notch is cut into both sides of the stick. He places the string loop on the thinner end and ties the cord lightly first at the thicker end—and when the tension is right, finally tight.

Mattias recommends using a Para Cord with a diameter of over 3 mm as a cord for bow drilling. Alternatively, strings made of rawhide, braided nettle fibers, or bast (parts of a deciduous tree inner bark) can be used.

Holding block

He prefers handy pieces of green hardwood of any kind. This eliminates the need for additional lubrication in the holding hole with green leaves or saliva. He has also used bone fragments, pine bark, shells, and stones as holding blocks. Civilizational waste (such as discarded glass bottlenecks) is not used here.

Underlay

Mattias places a wood chip from flattening the base wood under the V-notch to collect the drilled coal dust. He does not use his knife’s blade, dried leaves, or parts of birch bark for this.

Interesting details about Mattias Norberg’s bow drill process

Compared to other experts, Mattias completely debarks the bow and the spindle. He twists the spindle as usual with his right hand from the outside into the cord held in his left hand. Then, he holds the bow and spindle like a cross in one hand. This is very practical and a great advantage of the straight bow stick. The other hand remains free for other activities, and the bow is loaded and can be used for drilling at any time.

If the string’s friction around the spindle is insufficient (e.g., due to a string diameter that is too small), he wraps the string several times around the spindle, thereby increasing the contact surface. If there is sufficient friction on the surface but too little string tension, he does not reach further forward in the bow but pushes the string away from the bow outward.

When the spindle starts squeaking during sawing, he reduces the pressure and sprinkles some grains of sand into the drilling hole.

After pre-burning

Mattias collects the charred powder from pre-burning and places it under the V-slot on the underlay before the main burn process so that a layer of coal is already present to better absorb the embers.

After the embers have formed on the underlay under the V-slot, he scrapes every remaining coal particle from the drilling hole onto the underlay’s ember nest. He taps it very lightly so that the ember nest can settle better. Then he lets the embers rest for about one minute and transfers them—as usual—to the center of the prepared tinder nest.

In Sweden, Mattias prefers feathered, dry juniper bark as a tinder nest. If this is not available, he uses dry grass or other materials. He usually needs only a small amount of ignition material for the ‘bird’s nest,’ as he builds a holding fan with green fern fronds to place the ignition material. Transferring the burning material to the prepared fire pit is easier and safer.

Lessons learned from Mattias Norberg

- Go into the forest and use the wood for friction fire that can be found within an hour.

- Do not hesitate to use spruces as bow drill wood.

- The base wood should not be thicker than 1.5-2 cm.

- A straight and robust bow is best.

- Learn to hold the loaded bow in one hand.

- Use the charred powder from pre-burning for the primary burning process.

- If juniper bark is available in the area, use it for ignition.

Further readings about Fire-making on this website:

Creating fire with a magnifying glass

Hadza hand drill friction fire

Giant Fennel stalks for lighting fire

Batwa pygmies traditional fire lighting method

Manketti wood for friction fire lighting

Bushscout UK’s fire bundle basket

Fire lighting with Flint & Steel

Hand drilling in UK as taught by Dave Watson

Bow drill standard procedure by Dave Watson

Bow drilling in Australia by Gordon Dedman

Hand drill friction fire lighting in Australia

Creating fire by hand drill in Namibia

Australian friction fire wood species

.