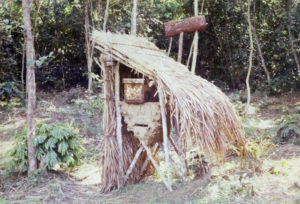

In recent years the shortage and expense of timber and corrugated iron sheet have encouraged people to use alternative materials for beehives. The range of substitutes includes old 200-liter fuel drums cut in half. Their ends removed, and their sides pushed together until they form an oblong approximately 50 cm wide to accommodate the top bars. Plastic basins and old truck fuel tanks have also been successfully converted. Hives have been built with bricks which have the additional advantage of being fire proof should a bush fire get out of control. Cheap hives can be made up from Nkooko (Raphia spp.) palm stems.

Different types of materials and designs for beehives

A wooden hive costs between $10 and $20 and usually lasts 4 to 5 years. Though the palm hive only lasts 2 to 3 years it is easy to replace, being made up locally and the top bars can simply be transferred to the new hive. Top bars are replaced following harvest or inspection as necessary. Instead of using purchased top bars many people now use straight pieces of Nkooko (Raphia spp.) of the correct width. As these have a groove on one side melted wax can be run along to provide a foundation for bees to begin constructing comb.

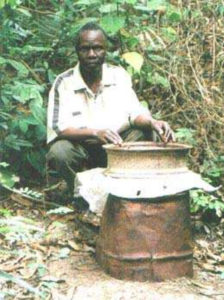

Mama Matondo of Muingu village with a hive made from burnt clay bricks set on the ground. A strong colony and plenty of ashes scattered round the hive discourages ants.

A 200-liter drum cut in half makes a good alternative beehive. The top and bottom have been removed. The drum should be sunk into the ground sufficiently to prevent ants etc. getting to the honey

training.

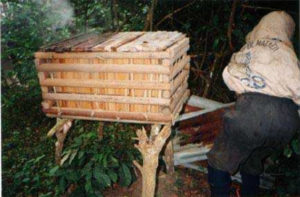

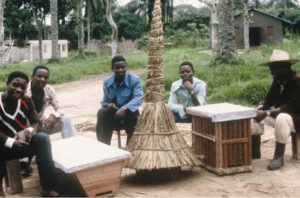

The Bimango hive, based on the Langstroth design, and made by a commercial beekeeper from Congo (Brazzaville). The hive is constructed from the midribs of raffia leaves and is pegged together with small raffia sticks instead of nails. Either top bars or frames are used. One or two supers are added to the brood chamber and a piece of fine mesh netting is used as a queen excluder.

Determine distance between top bars

‘One of the major problems with alternative beehives in Bas-Congo is getting top bars of the right width. They should always be 3.2 cm wide as this allows the bees to maintain “bee space” between combs. A simple way of measuring the width of a top bar is by using a bottle top from a soft drinks bottle. The top is actually 3 cm across but by the time a pencil line is drawn either side this will measure the correct width.

Where bees have built comb across two bars, first check that the bars are the correct width. If they are, one person should lift out the joined bars while the other separates the comb tying the loosed section back onto the bar with fiber. If the bars are not the correct width, there’s no use putting them back in the hive after straightening out the combs. Than the bees will continue to join combs to two bars. The bars must first be replaced.’ (Comment from Pam Gregory during a training course held at Kavwaya in 2008).

Lessons learned about alternative beehives:

- There is a wide variety of bee hive designs and materials, which can be used for this purpose

- All these designs have to be adapted to ambient weather and environmental specifics

- In the tropics, special care has to be taken to protect the beehives against ants and mammal predators.

_________________________________________________________________________________________________________

Text and all photos at this article © Paul Letham. The professional background and contact information of the author of this article can be found here.