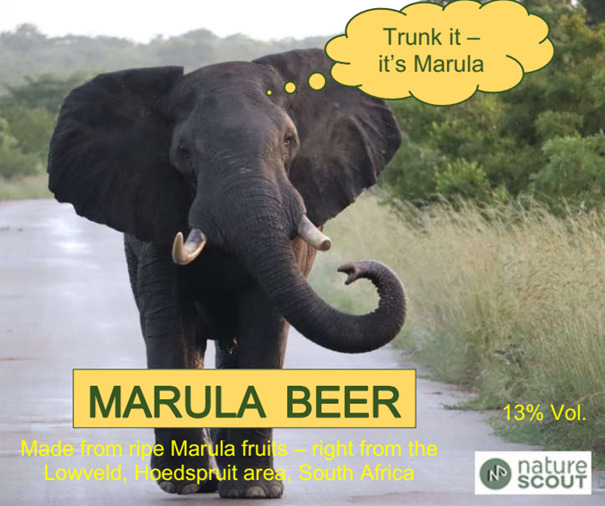

Marula season in Southern Africa typically occurs in February of each year. When Marulas (Sclerocarya birrea) get ripe, they turn from green to yellow and fall from the female Marula trees. On the ground, they ripen fully and will start fermenting after about a week. Areas under the trees are densely covered with Marula fruits in varying ripening stages during that time. These are used for producing Marula beer.

That’s also when elephants will travel far and wide to the known Marula tree locations and feast on these fruits. But it is untrue that elephants are getting drunk by them.

That is impossible, as Elephants are hind-gut fermenters and have a very short retention time of these fruits in their digestive system. Most of the Marulas they eat will be excreted again. Not only do elephants love marulas, but people do as well. At fruiting time, locals collect big bags and sell them next to the road. And many buyers are producing ‘Marula Beer’ from them, which is technically not a beer but a kind of cider. In this case, a Marula cider, which everybody – unknowingly why – is calling ‘Marula Beer.’

Producing this cider-beer or beer-cider is easy. And it is best to use fully ripe, yellow fruits, which already smell slightly of fermentation. Green fruits are still very sour for cider-making. After washing the fruits, the skins will be cut in half, and the kernels will be pressed out. Fruit flesh is still within the skins and on the kernels. Therefore, skins and kernels must be pressed to extract most of the juices. This is also the best way to eat Marula fruits: Squeezing out the juices and drinking these juices, as the fruit flesh is closely sticking to the kernel, and each fruit has to be kept in the mouth for a long time to nibble the fruit flesh. Squeezing and drinking are faster and easier.

After extracting the juices, a good amount of sugar should be added (about one big spoonful for every liter of juice) and some dry yeast to start fermentation faster. Now, the container with the concoction should be covered with cheesecloth and kept warm outside in direct sunlight. It will begin to ferment depending on natural and artificial amounts of sugar within the concoction, minimum and maximum temperatures, and the amount of yeast. The foam will take up cellulose fibers and other particles in the liquid. After ending the fermentation process, the foam will be converted to a solid layer, which can be easily removed. The remaining liquid is our Marula beer/cider, ready to drink.

We used too many green Marula fruits for the beer and too little sugar, so our concoction was always a bit sour. But the alcohol content and pleasant smell could compete with any Strongbow cider.

Lessons learned from making Marula Beer

- Just use ripe, yellow Marula fruits for the ‘beer’

- ‘Squeezing and drinking fresh’ is the best way to enjoy large numbers of Marulas and fill up the stomach

- Don’t save on sugar and yeast for the beer – sweet tastes better in the long run than sour

- When Marula beer is ready, a good braai with friends will make a memorable evening. Hopefully, with not too much of a headache afterward.

.